NEWS DETAILS

How to select and use power distribution units according to different industrial scenes?

Key Takeaways

In the era of rapid digital transformation, the demand for stable and efficient power supply is increasing in industrial environments such as data centers, mining fields and production workshops. Power distribution unit (PDU) is the core equipment for centralized management and distribution of power, and it is very important to ensuring the safe and continuous operation of all kinds of electrical equipment. However, with the diversification of PDU types in the market, how to correctly select and use them has become a key issue for many enterprises. This paper will make a comprehensive interpretation of PDU, focusing on rack PDU, C19 PDU, PDU socket and mine PDU to help you better understand and apply this power management device.

1. What is a power distribution unit (PDU)?

Power distribution unit (PDU) is a kind of electrical equipment, which acts as an intermediary between the main power supply and various electrical equipment, and is responsible for distributing power to multiple sockets, and at the same time providing protection and management functions to ensure efficient and reliable power supply. Unlike ordinary power strips that are mainly used for household scenarios, PDUs are designed for industrial or commercial-grade power needs, with higher safety performance and more flexible configuration options.

The core components of a PDU includes input interfaces, output interfaces, protection circuits and optional intelligent monitoring modules. Its working principle is to receive single or multiple external input power supplies, distribute electric energy to multiple output interfaces through internal wires, and automatically cut off the circuit by means of built-in protection elements (such as circuit breakers and fuses) when the current exceeds the rated value, so as to avoid equipment damage or safety accidents. PDU socket is the key component of the PDU, which directly affects the compatibility and power supply stability of the connected equipment. There are common C13 and C19 sockets, which can be selected according to the plug specifications of the connected equipment.

2. Unique Advantages of PDUs Compared to Ordinary Power Strips

Many enterprises may confuse PDU with ordinary patch panels, but in fact, there are essential differences between them. Especially, rack PDU, which is widely used in data centers and computer room, has obvious advantages compared with ordinary patch panels.

- More reasonable design and layout: Rack PDU is specially designed for 19-inch network switches and server racks, which can be perfectly installed in the rack, saving space and facilitate centralized management. They can easily create racks of any size by stacking and connecting equipment to meet different rack specifications.

- Stricter quality and standards: PDU adopts industrial-grade materials and production technology, and has CE certification (Certificate Number:M.2021.206.C68490) to ensure that it meets international safety standards. The shell adopts flame retardant and high temperature resistant materials, which can effectively reduce the fire risk.

- Comprehensive safety protection: PDU has multiple protection functions, such as leakage protection, overcurrent protection and overload protection, which can fundamentally solve the safety hazards such as frequent power failure, burning, poor contact and low load capacity leading to fire in ordinary patch panels.

- Stable performance, long service life: PDU has a longer trouble-free running time, is less likely to be damaged due to frequent plugging and unplugging, and generates less heat during operation, thus ensuring long-term stable power supply for a high-load environment.

- Flexible and convenient installation: PDU supports a variety of installation methods, such as rack-mounted and wall-mounted, and can be installed flexibly according to different application scenarios. At the same time, logos can also be customized to meet the individual needs of enterprises.

3. PDU product Specifications

PDU has various specifications, and enterprises can choose the appropriate model according to their actual power demand. The main performance indicators of PDU that we are concerned about are as follows.

| performance index | Detailed Parameters |

| Input Interface | single input, optional dual input, input interface can be up to more than ten options. |

| Output Interface | 2-40-bit output jack, with up to ten output interface options; C13 or C19 sockets are optional. |

| Maximum Output Current (jack) | 10A/16A/32A/63A /125A |

| Rack Compatibility | By stacking and connecting units, it is easy to create any rack size; It can accommodate any 19-inch network switch. |

| Customization | Can customize your own LOGO. |

| Certification | CE Certificate;Certificate Number:M.2021.206.C68490 |

Among them, C19 PDUs is very popular in the scene of high-power equipment, because its C19 sockets can withstand higher current and is suitable for power supply of high-power servers, industrial equipment, etc. The type of PDU socket is a key factor in choosing a PDU. The type of socket must be matched with the plug of the connected equipment to avoid poor contact or power failure.

4. The main application scenarios of PDU

Because of its stable performance and flexible configuration, Plus is widely used in various industrial and commercial scenes. According to the latest market research data, the global PDU market scale is growing steadily, and data centers and mines are the main growth drivers. (Data source: Global Power Distribution Unit Market Research Report 2025(Status and Outlook) – MarketPublishers.com: https://pdf.marketpublishers.com/bosson_research/power-distribution-unit-market-bosson.pdf )The major application scenarios include:

4.1 Data center

Data centers is the core infrastructure of the digital economy, which has a large number of servers, switches and storage devices, and needs stable power supply. Rack PDU is the first choice for data centers because of its rack-mounted design, which can be perfectly integrated with the server rack, saving space and facilitating centralized management. According to the data of Global Info Research, in 2024, the global PDU market revenue was about US$ 2024 billion, and data centers applications accounted for the largest share, accounting for 48% of the market share. PDU used in data centers usually selects high current output interfaces such as 16 a or 32 a, and some models are also equipped with intelligent monitoring functions to realize real-time monitoring of power consumption data.

4.2 Mining Field

Mining farms need a large number of mining machines to run continuously, which consumes a huge amount of electricity, so the demand for stable and efficient distribution equipment is extremely high. The mine PDU is specially designed for mining area, and has the characteristics of large current carrying capacity, many output interfaces and strong stability. It can meet the demand of power supply for multiple mining machines at the same time, and provide comprehensive overload and leakage protection to ensure the safe operation of mining farms. The output current of mining PDU is usually 63 a or 125 a, which can meet the high power demand of mining machinery.

4.3 Other scenes

Besides data centers and mining field, PDU is also widely used in lighting centers, computer room, financial centers, educational institution and production environment. For example, financial centers requires high stability of power supply, so it can choose PDU with dual input interfaces to ensure uninterrupted power supply; Production environment may be harsh, and PDU made of flame retardant and high temperature resistant materials can adapt to the environment.

5. Steps for Selecting and Using PDUs

Selecting the correct PDU and using it correctly is very important to ensuring the safe and efficient operation of equipment. The following are important steps for selecting and using PDU.

1. Clarify the application scenario and power demand: First, determine the application scenario (such as data center, mining farm) and the total power consumption of the connected equipment, the number of equipment, and the plug type. For example, if it is a mining farm, you should choose Mining PDUs with high current output; If it is a data center, rack PDU is more appropriate.

2. Determine the input and output parameters: select the input interface type (single input or dual input) and the number of input interfaces according to the field power supply situation. At the same time, according to the number of connected devices and plug types, determine the number of output interfaces and the socket type (C13 or C19) The maximum output current of the PDU should be greater than the total current of the connected devices to avoid overload.

3. Check the product certification and quality: When selecting a PDU, you must check whether it has relevant certifications such as CE certification (Certificate Number: M.2021.206.C68490) to ensure that the product meets international safety standards. At the same time, check the material and production technology of the product to ensure good quality and stability.

4. Choose the appropriate installation method: choose the appropriate installation method according to the site layout and equipment placement. For example, server racks in data centers can choose rack-mounted Rack PDU; In order to save space, the production workshop can choose wall-mounted PDU.

5. Correct installation and commissioning: Install the PDU according to the installation manual, ensuring that the wiring is correct and the connection is firm. After installation is completed, debug it, and check whether the input and output voltage and current are normal and whether the protection functions is effective.

6. Regular inspection and maintenance: During the use of the PDU, regular inspection and maintenance should be carried out, including checking the connection of the PDU socket, whether the shell is overheated and whether the protective element is normal. For smart PDU, it is also necessary to check whether the monitoring data is accurate and whether the remote control function is normal.

6. Frequently asked questions on PDU

Q 1: What are the different types of 1: PDU input?

A: There are three types of PDU input: single-wire input, double-wire input and IEC 320 input. Enterprises can select the appropriate input type according to their actual power supply situation. For example, dual-input PDU can be selected for scenes with high requirements for uninterruptible power supply.

Q 2: What is the difference between rack-mounted PDU and common power board?

A: Compared with ordinary power boards, rack-mounted PDU has the following advantages: more reasonable design and layout, stricter quality and standards, longer trouble-free operation time, safer protection against leakage, overcurrent and overload, less damage due to frequent plugging and unplugging, lower heating and more flexible and convenient installation. Suitable for industries with very strict requirements for power supply. It also fundamentally improves the potential safety hazards of conventional patch panels, such as frequent power failure, burning and fires caused by poor contact and low load capacity.

Q 3: How to choose the appropriate PDU socket type?

A: the selection of PDU socket type depends on the plug type of the connected device. Common types of PDU socket include C13 and C19. C13 sockets is suitable for general equipment such as ordinary servers and switches, while C19 sockets has higher current carrying capacity and is suitable for large-scale servers, mining machines and other high-power equipment. If the connected devices have different plug types, you can choose PDU of mixed socket types.

Summary

As a core equipment for centralized management and distribution of power, PDU plays an irreplaceable role in various industrial and commercial scenarios. Rack PDU, C19 PDU, PDU socket and mine PDU have their own characteristics, and their application are different. Enterprises should choose the appropriate PDU model according to their actual needs, and use and maintain it in strict accordance with the correct procedures to ensure the safe and efficient operation of equipment. With the continuous development of the digital economy, the demand for PDU will continue to increase, and the technical level of PDU will also be continuously improved, bringing more reliable power support to various industries.

Related Articles

The Power of Modular UPS Systems in Commercial Infrastructure

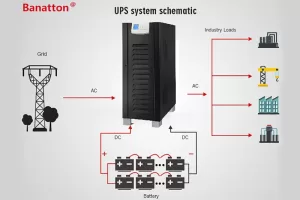

What is an industrial UPS?—How to choose an industrial UPS?

The Development of Voltage Stabilizers

Posts Categories

- News23